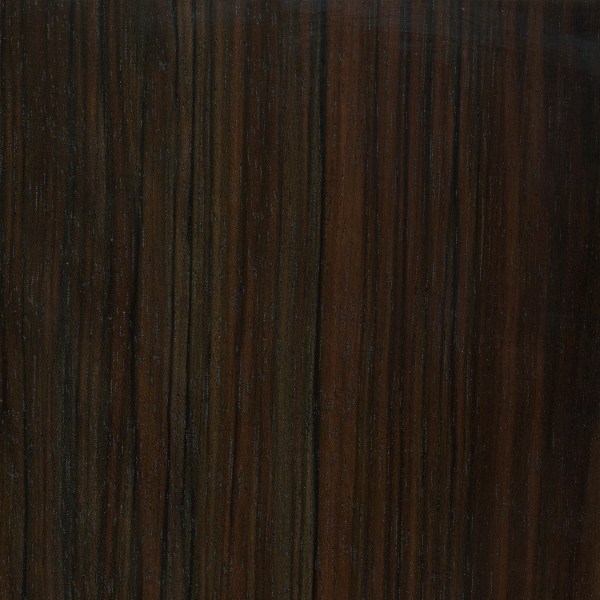

Ebony Wood Texture, Natural Wood Texture, High Resolution Texture Stock Image Image of ebony

While it doesn't produce a permanent finish, ebonized wood can be highly durable and is considered a valuable investment. In order to achieve this, you'll need a few supplies. The first step in ebonizing wood is to select a dark wood. Ash, for example, has a very open grain that allows the natural grain texture of the wood to show

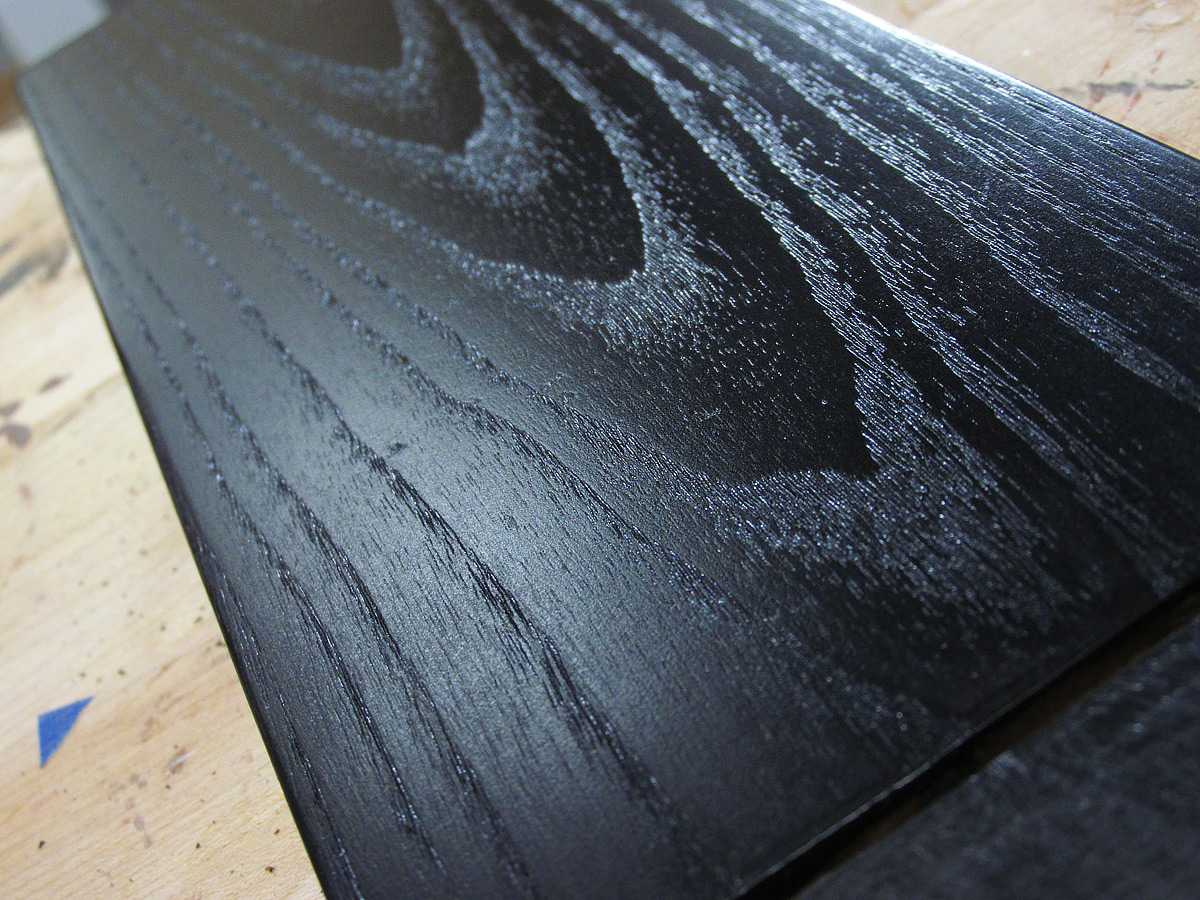

Ebonized Wood Surface PBR0579

When you ebonize wood, you're causing a chemical reaction that makes the material turn black. The benefit of this process is opacity. When wood is stained you can sometimes see the grain through the stain. When wood is correctly ebonized it becomes pitch black, and you won't be able to see the grain through the color.

Macassar Ebony The Wood Database Lumber Identification (Hardwood)

Start by dissolving a pad of steel wool (historically iron nails) in a quart jar of white vinegar. The iron ions produced by the breakdown of the steel wool react with tannins in wood to produce a black coloration. Stir the brew occasionally over the course of about a week.

natureebonywooddarkadmirawoodtexturelaminate1024x5… Flickr

Basic black In a litre of white vinegar dissolve a large hunk of old fashioned steel wool. Supermarkets often no longer stock the stuff, but you can usually get it from hardware stores. You need to use a lidded plastic container for this. You can buy these or reuse an old food container or similar.

Ebonizing Ash The Easy Way for Woodworking Projects Woodworkers Source Blog

Iron staining, or ebonizing, generally uses a reaction between iron oxide and the natural tannins in wood to create a natural-looking black that is actually created in the fibers of the wood rather than a stain sitting on top. This is why it is so durable. It is integral, not superficial. I have also found it to be very light-fast.

8matteebonizedoak Coryne Lovick Collection

Ebonizing wood is a pretty old technique. It has been used to create substitutes for real ebony wood because ebony is pretty rare and thus expensive. The classic method for ebonizing is based on a chemical reaction between iron acetate and the natural wood tannins which produces a dark stain.

Ebony wood texture stock photo. Image of grain, construction 32876692

Ebonizing wood is a wonderful way to create a dark, graphic look that emphasizes the form of a piece. The steel wool and vinegar recipe I use gives depth and darkness to heavy-tannin woods like walnut and oak, while still allowing for aspects of the grain to shine through.

Ebony dark wood fine texture seamless 04287

Steps to Ebonize Wood with Steel Wool and Vinegar: Look at the steps here for a better understanding; Prepare the wood: start with preparing the wood. Ensure the wood is sanded, with no paint or varnish. Create the wool and vinegar Solution: the second step involves creating the perfect solution for ebonizing wood.

Ebony dark wood fine texture seamless 04287

Ebonizing wood is not the same thing as simply coloring wood with ebony stain. When you ebonize wood, you're causing a chemical reaction that makes the material turn black. The benefit to this process is opacity. When wood is stained you can sometimes see the grain through the stain. When wood is correctly ebonized it becomes pitch black, and.

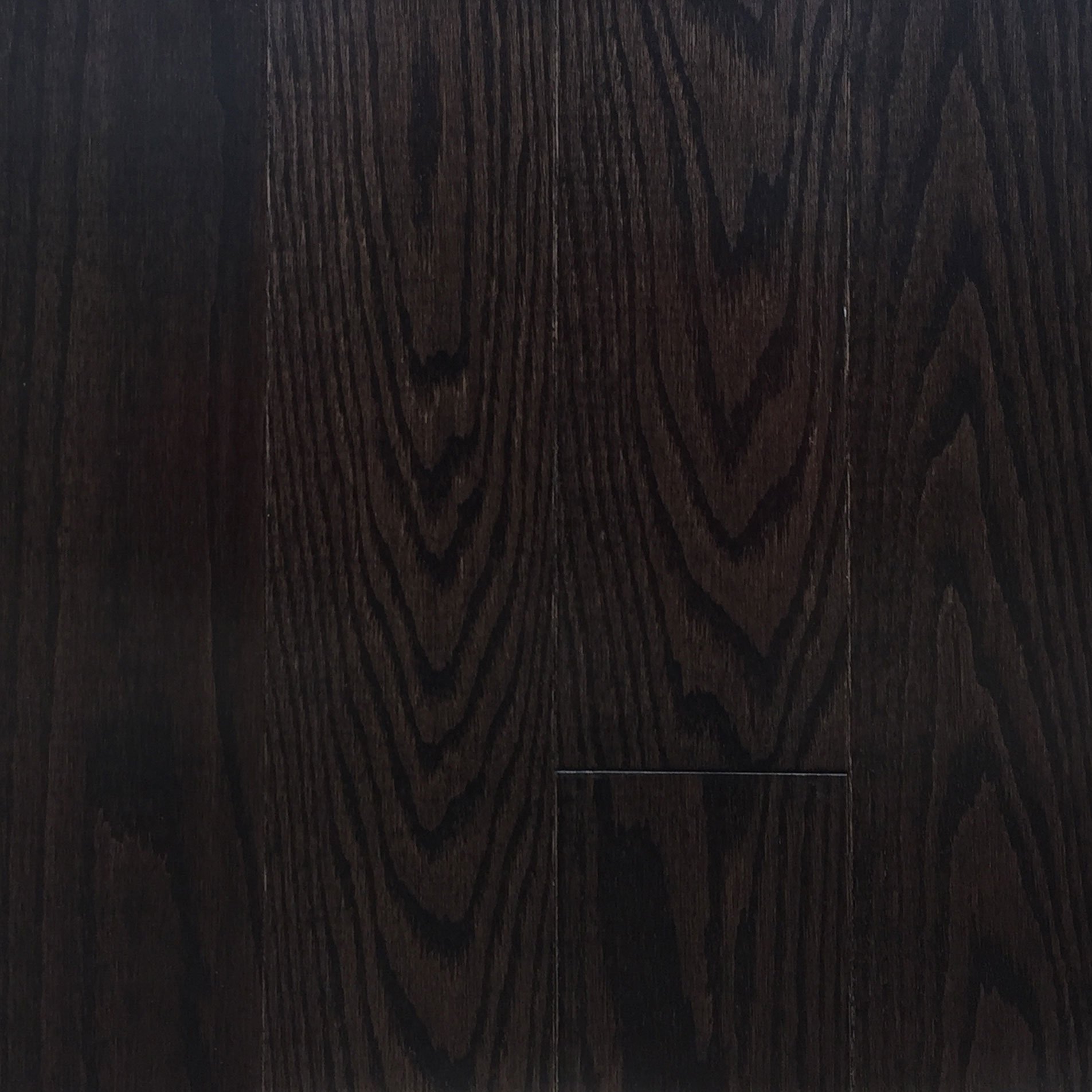

Pergo MAX Embossed Oak Wood Planks Sample (Ebonized Oak) at

Follow us at: https://www.facebook.com/woodsmithmagazine/https://www.facebook.com/woodsmithshopshow/https://www.woodsmith.comLogan walks us through chemicall.

Ebony Wood Grain Blake Solutions

The trouble with mixing your own black dye for ebonizing wood is that it often comes out too gray, or sometimes blueish. The Solar-Lux Jet Black dye turns out to be a good answer to these troubles. It doesn't raise grain and it's solid black. Take a look for yourself, you'll see how easy, quick, and effective this is.

Ebony Red Oak LV Hardwood Flooring Toronto

Ebonizing is a process of staining wood naturally without affecting its natural beauty. It is a way to put emphasis on your wood's graphic look. Ebonizing is also called iron staining. 1. Things to Consider When Ebonizing The wood to use Ebonizing relies on iron and how it will react with the wood's natural tannic acid.

Ebony Wood, आबनूस की लकड़ी in Strand Road, Kolkata , Khemka Woodcraft Pvt. Ltd. ID 3472916497

Introduction: What is Ebonizing Wood and Why Achieve an Ebonized Finish? Ebonizing is a specialized process that allows you to darken the color of any type of wood to a rich, ebony hue. This popular finish has been used for centuries in furniture making and interior design, offering a classic, timeless appeal. It takes patience,

Finishes Scott Lamp Company

Ebonizing wood is the effect of darkening or blackening a naturally lighter colored wood to appear more like black ebony wood. Ebonized wood can be created with a chemically reactive process or other means to color the wood black, like ebony, while still allowing the wood grain to show through.

Ebony (wood Texture) Image & Photo (Free Trial) Bigstock

Small jar Sponge Brush Black Tea Ask Question Step 2: Wash Steel Wool Wash the steel wool with soap and water to remove any residual grease that may be present from the manufacturing process. Ask Question Step 3: Add Vinegar Place the steel wool in the jar and slowly pour in the white vinegar, leaving a little headspace. Ask Question

Heritage Mill Brushed Hickory Ebony 3/4 in. Thick x 4 in. Wide x Random Length Solid Hardwood

How to Ebonize Wood 4 minute read 1 Shares Table of Contents Hide Ordinary wood to ebony What you will need Steps on how to ebonize wood 1) Creating the staining solution 2) Preparing wood 3) Lightly sand the raised grain using 220-grit sandpaper 4) Applying the stain 5) Drying your work 6) Buffing the surface Conclusion